Located in the idyllic Franconian Forest, porcelain „made in Germany“ is manufactured since 1912 in Steinwiesen.

The success story of the family-owned company, founded as a doll’s head factory, began with the triumphal march of insulating electronical porcelain.

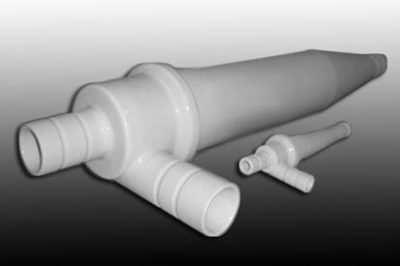

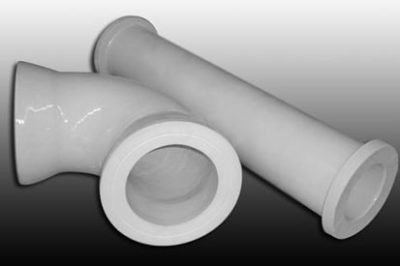

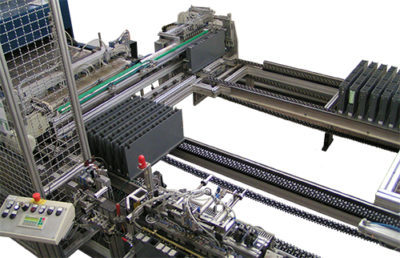

Today, with 75 employees, KOBER is expert in special products made of the precious material porcelain. From efficiently producing large-volumes to handcrafted individual pieces, KOBER is a reliable supplier for mainly industrial customers. Our own mold construction and mechanical engineering enables maximum flexibility, quality and punctuality.

The professional staff of KOBER realizes even difficult porcelain product ideas with passion and experience.

Let yourself and your customers get inspired by this timelessly beautiful material.